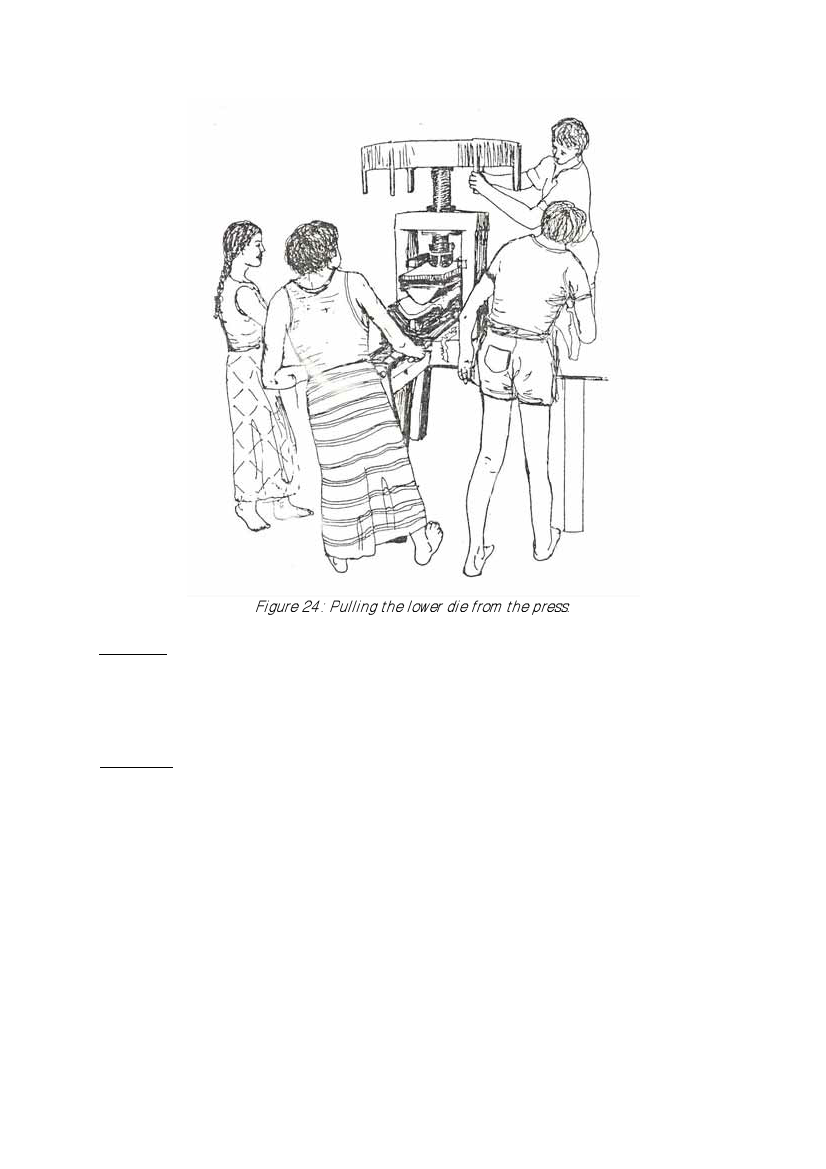

Figure 24: Pulling the lower die from the press.

TRIMMING

The tile is now taken to the trimmers. They first remove all remaining flashing, and correct

small nicks and bruises on the tile. On some tiles they will slap each side of the tile with a

light slat to leave a completely smooth finish.

STACKING

The tiles are then put onto the racks to dry. Tiles may be carried by hand, or taken by cart

depending on how far the racks are from the press. To get tiles to the highest racks workers

will stand on boards resting on the racks on either side of the aisle, handing the tiles up. Tiles

should be dry and kiln ready in between five and 10 days depending on the local conditions.

If necessary the drying can be speeded up by heating the air using oil drums full of

smouldering wood chips placed in the aisles. Of course, faster drying of tiles saves on drying

racks and thus factory space.